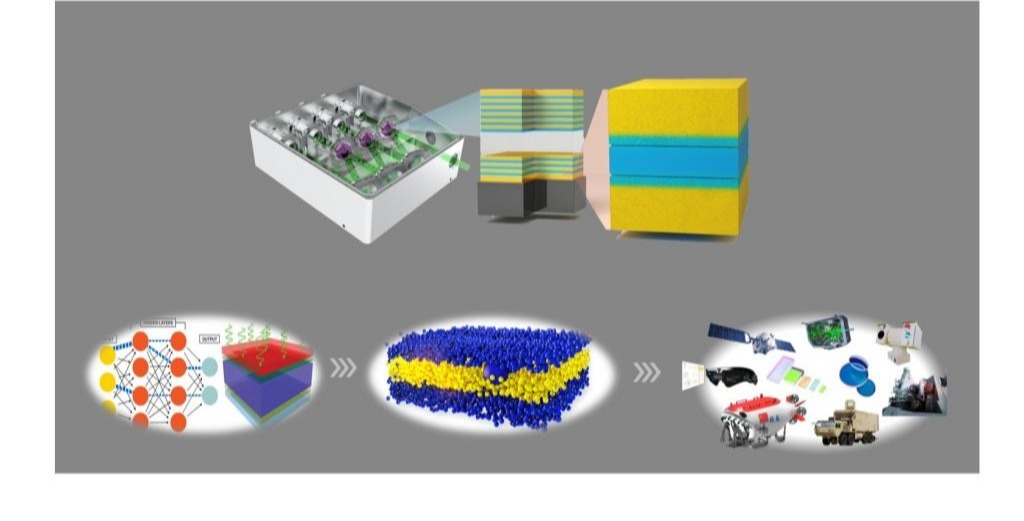

High-power laser systems and equipment have a significant impact on the solution of major scientific problems, the progress of the national defense equipment, and the development of the high-tech industries, whose core components as well as the weakness are the laser coatings. The research group built a development platform that includes the optimization design of laser coatings,all-flow-control preparation, performance characterization, and system application. They studied the interaction mechanism between the laser and materials and explored the loss mechanism and control techniques of laser coatings. An effective regulation of the coating structure, optical properties, and environmental adaptability has been achieved, which contributes to the development of the high-power laser system.

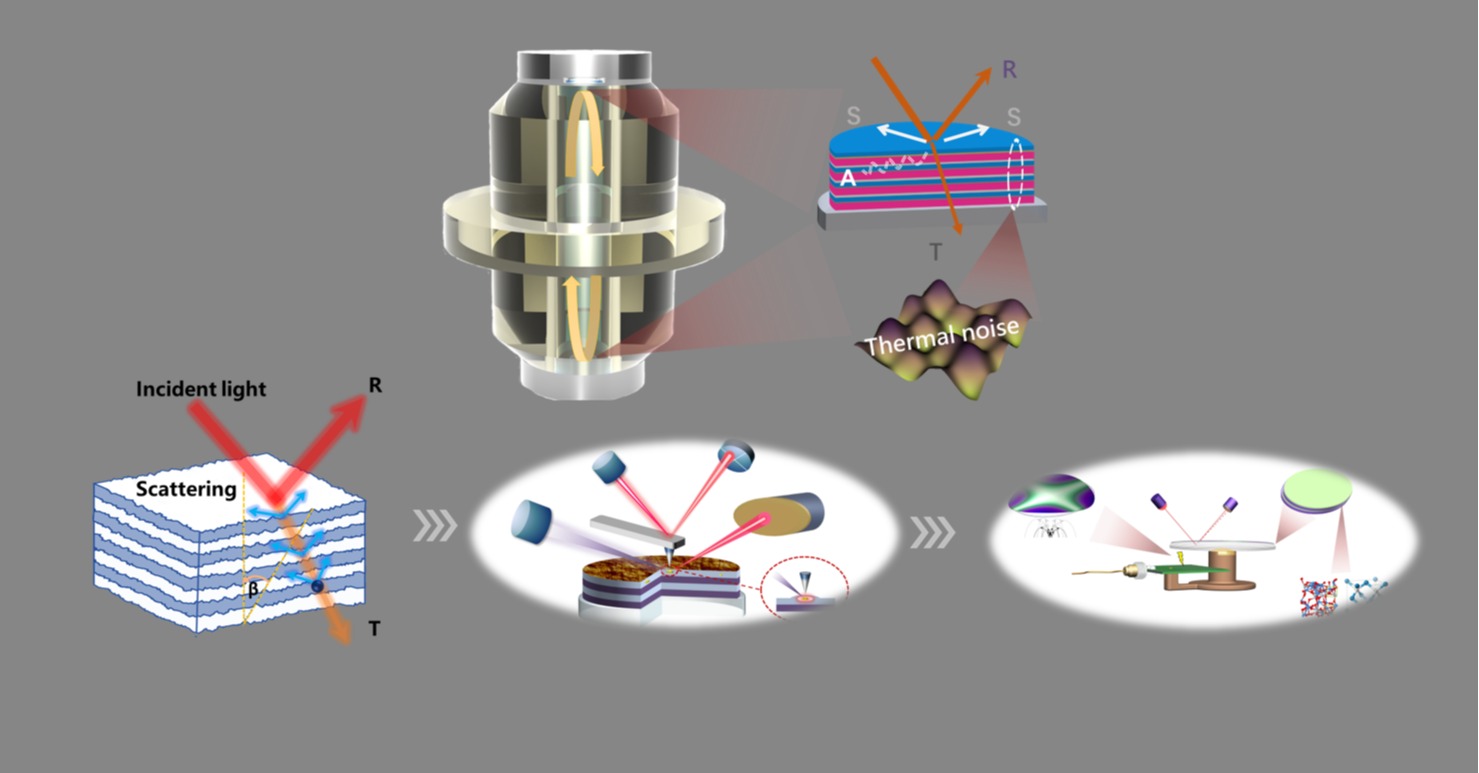

Corresponding to the great demand of precision measurement, the physical mechanism of coating has been studied, including absorption, scattering, and thermal noise. The accurate characterization techniques of defect absorption and mechanical loss have been developed, with the materials and processes optimized for the preparation of ultra-low-loss laser coatings.

The division has been committed to the research regarding the all-flow-control preparation of the multi-functional high-power laser coating, including the coating damage mechanism, design and control of the multi-physical field, and regulation of the microstructures.

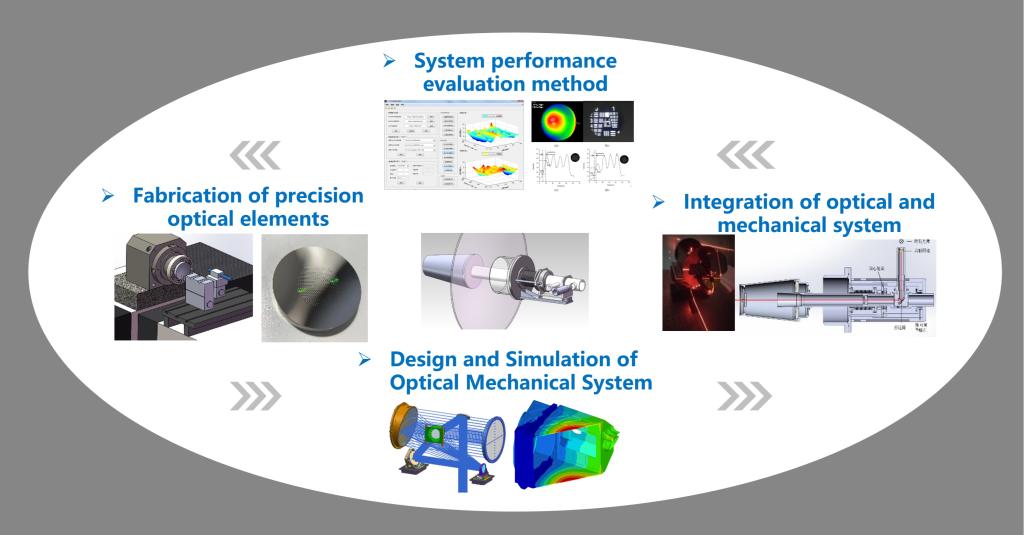

Based on the manufacturing technology of precision components and optical coating technologies, the research and development of precision optical systems in the ultraviolet, visible and infrared bands are carried out. The object-oriented design method of a complex optical system has been proposed, the key technology of high-precision integrated assembly of optical system have been developed, and the method of performance inspection and evaluation of the optical system has been established. In addition, a precision opto-mechanical research and development platform has been constructed, which includes the process of “optical design, structural design, component manufacturing, assembly and integration, and performance evaluation.”

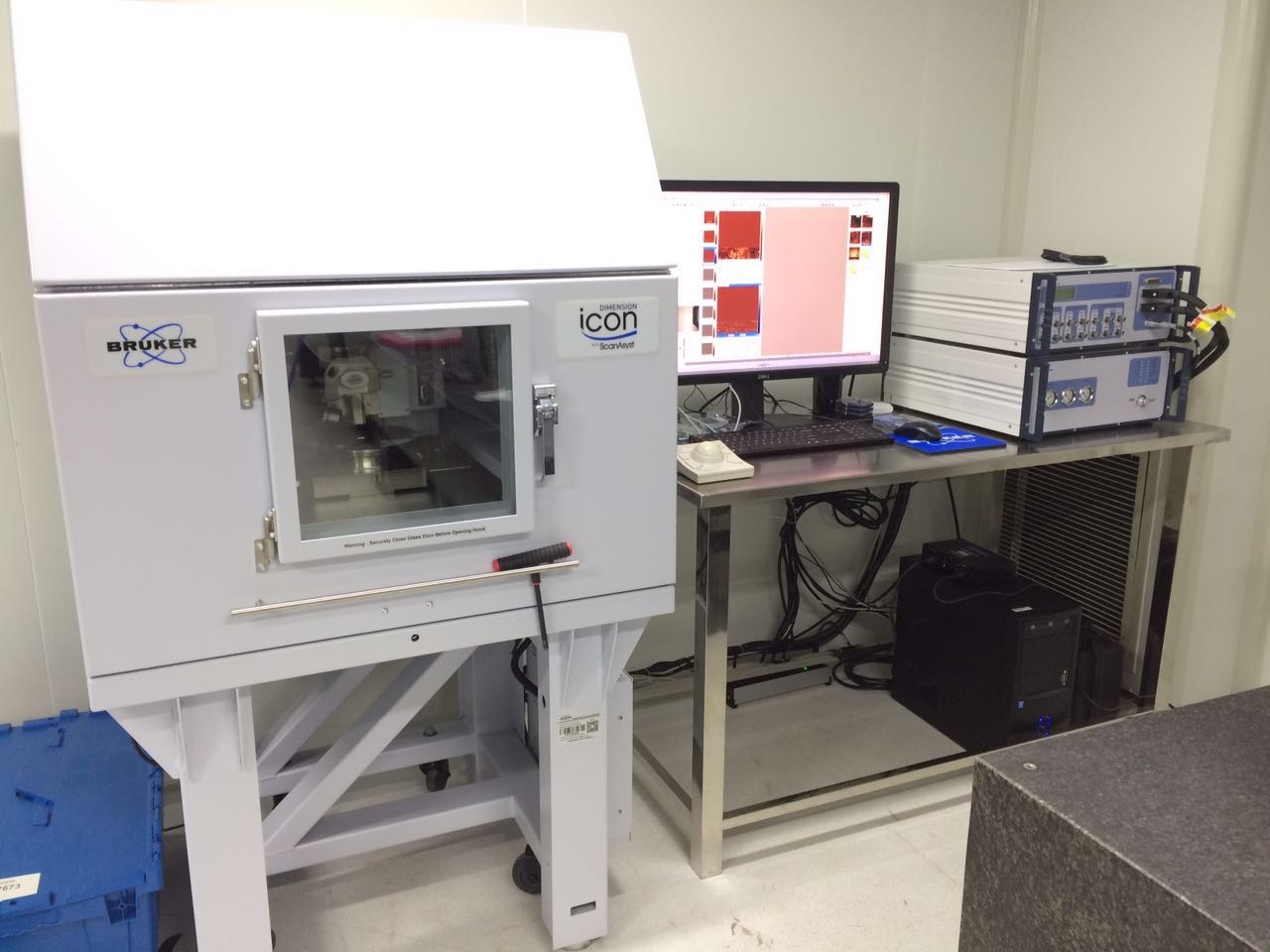

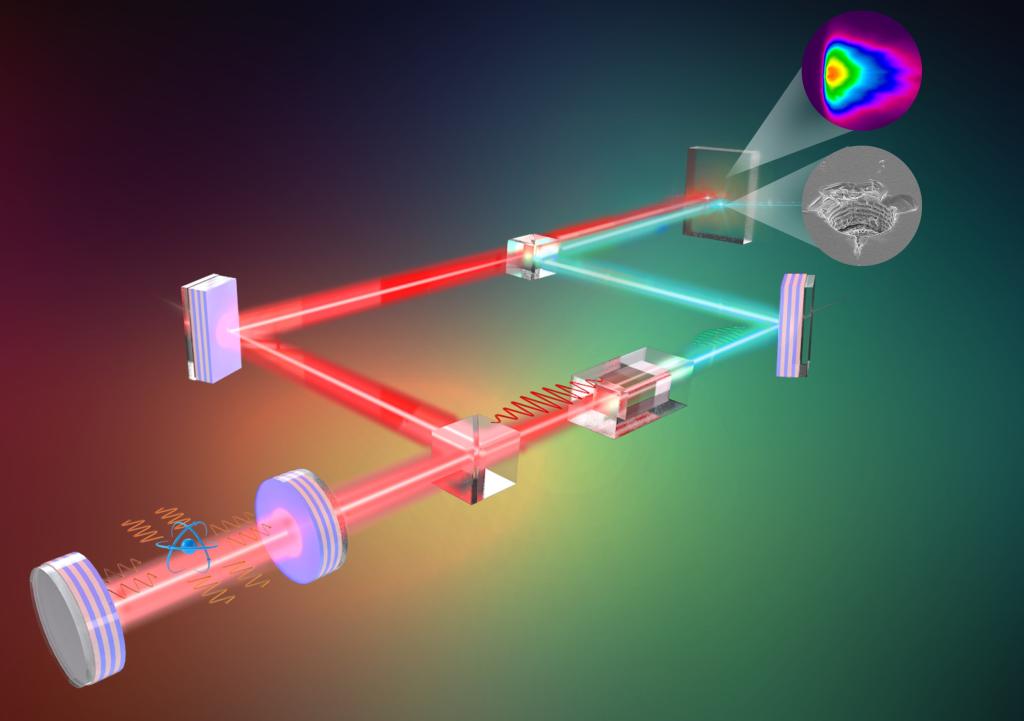

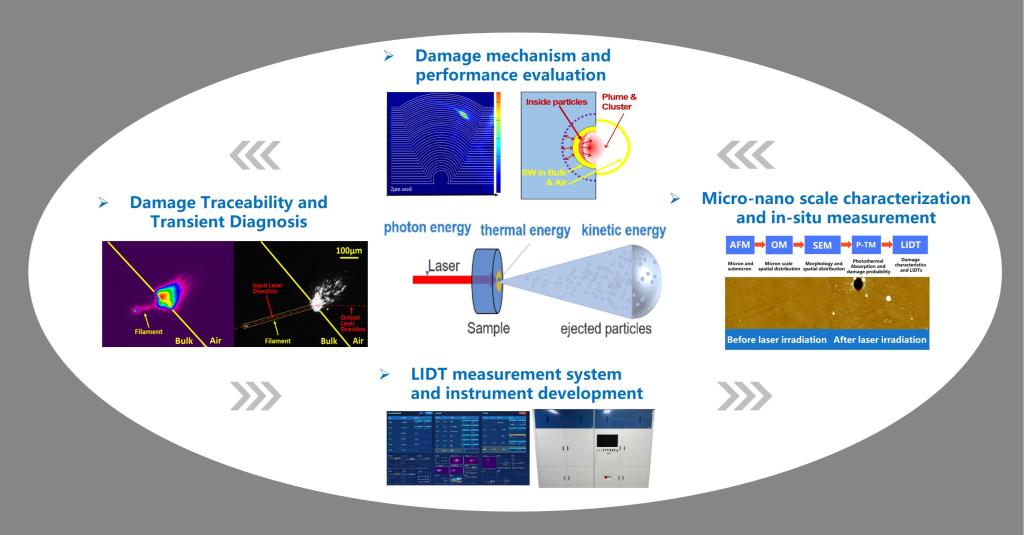

To address the national demand of the high-power laser equipment and engineering tasks, an automatic laser-induced damage threshold testing system with nanosecond and femtosecond pulsed lasers have been established. The system enables the automatic detection, location re-detection, transient diagnosis, and in-situ measurement of micron- and submicron-scale damages. The test process is based on ISO standards and raster scanning methods. The development process is as follows. From 2008 to 2009, the system was preliminarily completed, featuring semi-automatic and manual assistance. From 2010 to 2011, the improvement was achieved to enable fully automatic measurements and parameter acquisition. From 2012 to 2013, an iterative update was applied with optimized measurement strategies and manual re-inspection standards.

2018 PhD Candidate

2019 PhD Candidate

2019 PhD Candidate

2019 PhD Candidate

2020 PhD Candidate