Nano-positioning technology serves as the foundation of modern precision engineering. Take the integrated circuit field as an example: the ultra-precision positioning technology for large-stroke wafer stages is one of the key core technologies in lithography machines. In the allocation of overlay errors, the nano-positioning error of the lithography machine's wafer stage typically accounts for one-tenth of the total overlay error, requiring a positioning accuracy reaching the sub-nanometer level. This imposes strict requirements on the accuracy and reliability of nanometer displacement positioning calibration technology. Traditional calibration technologies, limited by a single traceability link, struggle to balance high precision, large stroke, and high environmental adaptability, restricting their application in the field of ultra-precision positioning.

To address this challenge, the research team led by Researcher yushu Shi at the National Institute of Metrology of China, in collaboration with Professor Xinbin Cheng’s team at the National Metrology and Testing Center for Micro-Nano Inspection Equipment in the Integrated Circuit Industry (Shanghai), developed a grating diffraction interferometry-based calibration device for micro/nano displacement and positioning, based on the one-dimensional chromium nano-grating standard (ID: GBW13982). This provides crucial technical support for the expansion and capability enhancement of China’s micro/nano displacement and positioning calibration traceability chain. The joint research results have been published in the first issue of Measurement Science and Technology in 2025.

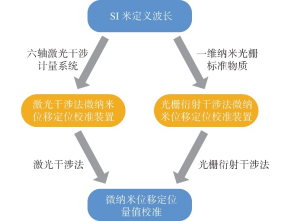

Figure 1: Dual traceability chain for micro-nano displacement positioning calibration device

This research extends the traditional single-traceability laser interferometry chain by creatively incorporating grating diffraction interferometry, thereby forming a dual-traceability scheme. Within the traceability chain that references the laser back to the wavelength standard, a six-degree-of-freedom laser interferometer system is employed to measure displacements and rotational angles along the X, Y, and Z axes of the translation stage. The short-chain configuration greatly minimizes the propagation of measurement errors. By employing a 633 nm laser wavelength, the measurement results are directly traceable to the SI definition of the meter. In the grating pitch traceability chain linked to the wavelength standard, the core component is the first class of national certified reference material (one-dimensional chromium nano-gratings) developed by Professor Cheng Xinbin’s team. A Littrow-structured grating interferometer is constructed, where the grating pitch is defined and directly traceable to the laser wavelength through atomic lithography. When the grating moves along its vector direction, the Doppler effect causes frequency shifts in the diffracted light. By combining ±m order diffracted beams, the phase of the interference signal changes by 2π for every 1/2 grating pitch displacement, that is, the grating pitch is the measurement reference of the grating displacement system, which can be directly traced back to the definition of "meter".

Figure 2 (a) (b) Physical and schematic diagrams of a six axis laser interferometer; (c) (d) Physical and schematic diagram of grating interferometer

This research innovatively integrates laser interferometry and grating diffraction interferometry traceability systems, overcoming the limitations of single traceability chains. Both dual traceability chains eliminate reliance on intermediate variables, achieve direct traceability, reduce error accumulation, and lower requirements for equipment and environmental conditions. It provides standardized, high-accuracy references for precision measurements in related industries, contributing to the improvement of China’s metrology system for micro-nano positioning platform calibration and offering critical technical support for advancing micro-nano positioning technologies. The work was funded by National Key Research and Development Program of China and the Key Areas Basic Research Fund of the National Institute of Metrology, China.